Made in USA

In-House Manufacturing Capabilities

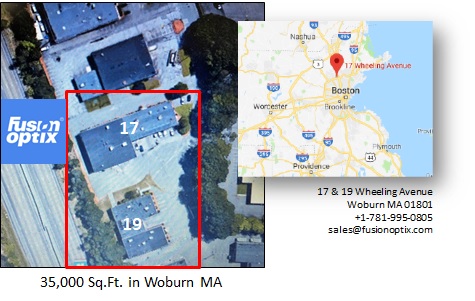

Fusion Optix is a "Made in USA" focused company. We have invested heavily in a 55,000 sq.ft. manufacturing and engineering facility in Woburn MA, just a short 20 min drive from Boston's international Logan Airport.

Our Manufacturing Philosophy

Fusion Optix believes that a well optimized optical system requires not only a proper strategy regarding changes in product design but also implementation of proper manufacturing and quality control systems. The challenge is often not product customization itself but doing so in a profitable way. Fusion Optix has developed a broad implementation approach which enables a reduction of lead time for products and quotations, making for faster responses to customer inquiries, fewer transfers of responsibility and specification mistakes, reduction of resources spent on specification of custom products, and facilitate optimization of the products according to customer needs.

The Fusion Optix production facility houses a variety of equipment and capabilities mostly in Class 10,000 to Class 1000 cleanrooms. Our rapid prototyping and manufacturing capabilities are highly flexible and our Solutions Group engineering and product development staff is on hand to help scope any work as well as assist with any customer design questions and system-related issues. Our goal is to offer our customers the fastest and most economical route to achieving optimized and tailored product performance.

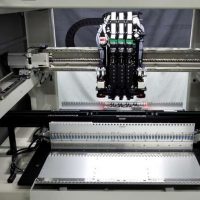

LED Engine Assembly - Suface Mount (SMT) & PCB Assembly

Fusion Optix has invested heavily in equipment for in-house assembly of LED engines. This includes 8 automated “pick-and-place” PCB assembly machines housed in a Class10,000 cleanroom. The equipment has been designed to work with the latest LED packages and can also be used for placing AC power and control electronics on board. Capable of PCB assembly up to 4ft lengths. In addition Fusion Optix has 2m integrating sphere and a range of quality control equipment to implement its proprietary SureBIN™ technology.

Profile Extrusion

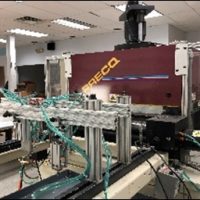

Fusion Optix has invested heavily in a broad range of in-house manufacturing capabilities for the profile extrusion of plastic (PMMA, PC, COC, SAN) optical components. We have 2 profile extrusion lines in-house and are able to cover anything from linear profile, sheet and film extrusion through to optical coatings and laser engraving and cutting. Equipment is in-house at our Woburn MA facility and in most cases enclosed inside Class10,000 cleanrooms.

Cast Film & Sheet Extrusion

Cast film and sheet extrusion capabilities for the production of plastic (PMMA, PC, COC, SAN) optical materials. We cover anything from linear profile, sheet and film extrusion through to optical coatings and laser engraving and cutting. Equipment is in-house at our Woburn MA facility and in most cases enclosed inside Class 10,000 cleanrooms.

Optical Coatings (Roll-to-Roll & Sheet)

Slot die and reverse roll coating based systems for the precision coating of clear films and sheet. Solvent lamination of optical films to substrates. Capabilities housed in cleanroom with additional localized clean environments.

Die-cutting & Precision Converting

Fusion Optix can help design and prototype new optical components and advanced LED lighting systems on an accelerated timeline. Our in-house capabilities in 3D printing and quick turn PCB board design enable us to produce new optical components and LED light engines in a matter of days. In addition our off-the-shelf solutions enable a faster integration of LEDs in general and technical lighting.

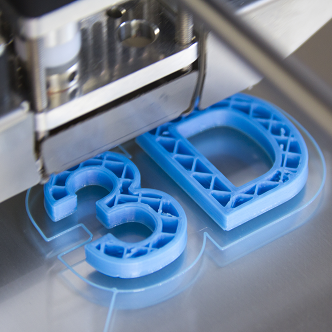

3D Printing & Rapid Prototyping

Fusion Optix can help design and prototype new optical components and advanced LED lighting systems on an accelerated timeline. Our in-house capabilities in 3D printing and quick turn PCB board design enable us to produce new optical components and LED light engines in a matter of days. In addition our off-the-shelf solutions enable a faster integration of LEDs in general and technical lighting.

Applications Engineering

Fusion Optix applications engineers are on hand to help customers make the most effective incorporation of our products into their designs, or to help build designs around our components. In many cases they do this free of charge.

Quality Assurance

Fusion Optix has a strong quality mind-set and has established a range of state-of-the-art capabilities to help our customers ensure performance and reliability as they seek to adopt our unique range of products and solutions. We share common quality goals with our OEM customers. Our approach is designed to support cost effective offerings that satisfy even the most stringent of OEM and industry standards.

Solutions Group - Engineering & Product Development Support

Solutions Group is a dedicated in-house innovations and technical support group based in Woburn MA. The Solutions Group team of engineers and scientists is dedicated to the goal of helping OEMs adopt our ground breaking Intellectual Property platform. We have always invested heavily alongside our customers in new ideas and innovation partnerships. Solutions Group combines the science and technology elements of what we do with a strong strategic business development focus.